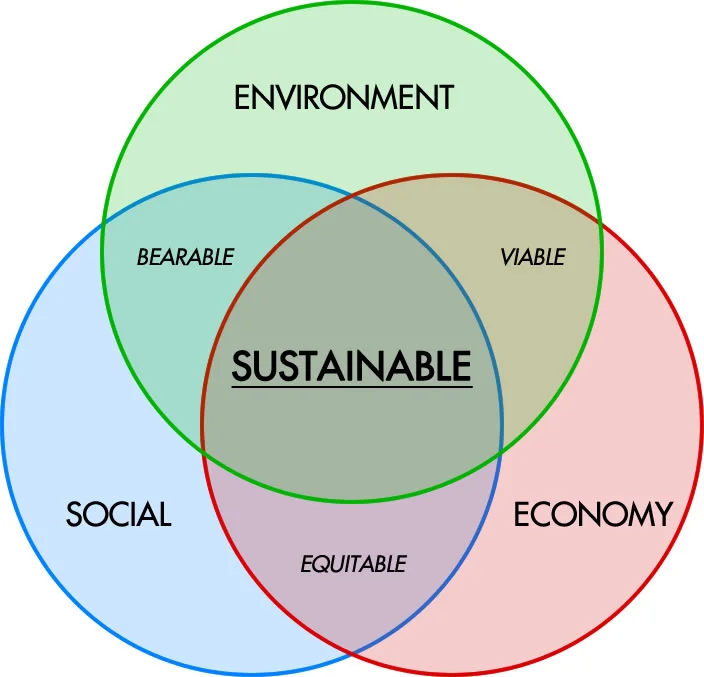

“Sustainability creates and maintains the conditions under which humans and nature exist in productive harmony, that permit fulfilling the social, economic, and other requirements of present and future generations.”

Lignocellulosic materials have long been recognized as sustainable sources of biofuels and biomaterials. However, the biomass cell walls are naturally resistant to any modification or deconstruction. This natural tendency of the biomass cell walls to resist change is collectively known as "biomass recalcitrance" or "biomass inertia".

ECPI specializes in providing innovative solutions to overcome biomass recalcitrance in order to produce an engineered biomass product for a variety of applications. This process is called "biorefining". ECPI commercializes the art of biorefining to produce sustainable, engineered biomass feedstocks for renewable power, fuels, chemicals, and carbon to achieve socio-economic optimization of energy and environment.

Successful biorefining commences with controlled dehydration. ECPI's state of the art, patented Z8 rotary dryer provides controlled dehydration of various biomass species to a low moisture content while simultaneously preventing the production of volatile organic compounds (VOC's).

ECPI proposes the synergistic pathway called "Food First": that growing more food will provide more biomass residues that can be biorefined to produce engineered feedstocks for energy, fuels, chemicals, and other biomaterials.

Growing more food will serve to solve the problems of global hunger and malnutrition, create sustainable jobs with energy independence, and provide sustainable feedstocks for clean energy and a clean environment.